TiMOTION's MA2 series electric linear actuator was specifically designed for applications that face harsh working environments, requiring a heavy-duty construction and durability. Additionally , the MA2 has an optional T-Smart version. Embedded with a driver board, the MA2 allows for easy integration with a variety of control interfaces, eliminating the need for an external control box.

The MA2 is available in two T-Smart alternatives:

1)T-Smart Advanced

The actuator is controlled by an embedded PCBA, providing advanced functionality and real-time feedback.

The T-Smart Advanced configuration allows for synchronization of up to 8 actuators, as well as providing accurate position feedback through a variety of options (Hall, Hall-Pot., PWM).

*TiMOTION’s software program, PGMA, exclusively supports the T-smart Advanced configuration, providing the user autonomy to adjust many parameters such as speed, stroke limits, soft-stop, soft-start, and much more.

2)T-Smart Bus Communication

The actuator is controlled by the customer's control system, such as their ECU or PLC.

-SAE J1939: This protocol provides seamless integration with CAN bus SAE J1939 interfaces,

the standardized communication protocol commonly implemented in off-road vehicles and other industrial applications.

-Modbus: This is a serial communication protocol predominantly used in industrial automation and process control. The T-Smart Modbus protocol can be smoothly incorporated into existing industrial systems through its interface.

General Features

Max. load: 8,000N (push); 4,000N (pull)

Max. speed at max. load: 5.1mm/s

Max. speed at no load: 52.5mm/s

Retracted length: ≥ Stroke + 131mm

IP rating: IP69K

Certificate: UL73, EMC

Stroke: 25~1000mm

Output signals: External signal of actuator, mechanical Pot., NPN Hall sensors

Voltage: 12/24/36/48V DC; 12/24/36/48V DC (thermal control)

Operational temperature range: -40˚C ~ +85˚C

Operational temperature range at full performance: +5°C~+45°C

Manual drive

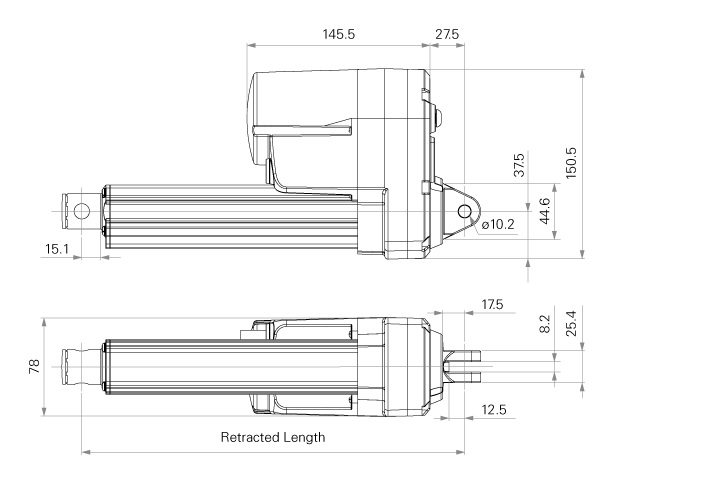

Standard Dimension (mm)

Power And Performance For Your Industrial Equipment - MA Series Electric Linear Actuators

MA Series Industrial Linear Actuators

Industrial Actuators and Related Applications

Document Downloads

- Healthcare: hospital beds, tables, medical chairs, and carts, patient lifts, mobility aids...

- Industry: industrial and agricultural vehicles, automated equipment, intralogistics transport equipment, window opening and ventilation systems...

- Workspace: sit-stand desks, workstations, laboratory benches, control stations, display units...

- Home: sofas, recliners, kitchen furniture...

- Parallel electric actuators: The motor is parallel to the worm gear. Parallel electric linear actuators are usually driven by spur gears, which offer a wider range of gear ratios. These actuators allow for a greater range of loads and speeds but aren’t as quiet as actuators with worm gearing.

- Right angle or "L" shaped electric actuators: The motor is placed perpendicular to the worm gear. A worm gear usually drives L-shaped electric linear actuators. These actuators offer fewer gear ratio choices than spur gear motors but are quieter and offer increased irreversible force.

- In-line electric actuators: The motor is in line with the worm gear. In-line electric linear actuators, therefore, have a longer retracted length. They are usually driven by a set of planetary gears and are specifically designed to fit into tight spaces. However, they have a higher noise level.

- Dual engines: Dual motors operate in two different directions, independently or simultaneously. They are usually driven by gears with a worm wheel and, therefore, offer a quieter movement.

- The electric sliding actuators: Electric slide actuators allow linear movement without the use of an outer tube. The front attachment is linked to the nut, which moves along the worm gear.

- Geared motors: Gearmotors allow the design of economic and versatile systems when combined with one or more worms. Compact, they are usually driven by gears with a worm wheel and are an ideal choice for achieving mechanical synchronization.

- Electric lifting columns: We manufacture lifting columns for industrial, medical, and ergonomic applications. They allow the vertical movement of high loads while maintaining a high level of stability.

- Load to be pushed

- Required speed of movement

- Duty cycle

- Available installation space

- Application environment requirement

An electric linear actuator is an electromechanical device mainly composed of a motor, a set of gears, and a motion mechanism in the form of a worm and tube. It converts the motor’s rotary motion into linear motion by driving the gears and worm gear, By providing linear movement, it can be integrated into any equipment to push, pull, lift, lower, position, or orient a load.

Electric actuators are easy to install and operate. They require minimal maintenance and deliver accurate, efficient, safe, ergonomic, and environmentally friendly movement. These actuators can be easily integrated into industrial, medical, home furniture, or ergonomic desk applications to push, pull, raise, lower, or orient a load. With increasing power and sophistication, they can operate in any direction, gradually replacing hydraulic and pneumatic systems that are considered too constraining or cumbersome.

Thanks to their incredible versatility, electric actuators offer numerous possibilities for movement, enabling the design of ergonomic and comfortable equipment. By adapting to individual needs, they enhance accessibility and ergonomics, promoting easy integration. Electric actuators facilitate a wide range of tasks, enhancing performance and productivity in various activities. This is why they are found in most everyday equipment across diverse applications:

There are many types of electric linear actuators. Actuators, columns, gear motors, and others all have their specificities and their strong points. Discover the list of the different types of actuators that TiMOTION produces and adapts to the needs of equipment manufacturers:

It is important to select an actuator that can meet the requirements of the application. Every application has a list of unavoidable conditions. To choose the right electric linear actuator, you must first consider your application's constraints and technical priorities:

At TiMOTION, technical experts will work with you throughout your project to provide the best solution for your application. With a vertically integrated business model, TiMOTION offers highly customized solutions to meet the unique requirements of various applications, ensuring that the integration of electric linear actuation is seamless and efficient.

TiMOTION works exclusively with Original Equipment Manufacturers (OEMs). Therefore, we do not stock, distribute, or sell any single product. For any questions, replacement, or purchase of an individual component, please contact your specific equipment manufacturer. Components are often covered by their warranty and may be available in stock for single unit distribution.