2021/05/03

Electric Motion Technology for Automated Guided Vehicles

뉴스와 기사

Automated Guided Vehicles conquer all sectors

Automated Guided Vehicles (AGVs) are increasingly more common in professional environments. Equipped with electric linear actuators, they offer many adjustments and features, making users’ daily work easier.

The development of international trade and e-commerce, the increase in production and exchange of goods, and the expansion of operating areas have raised new economic, social, ecological, and sanitary challenges, leading to the increasing automation of companies to meet them.

Regardless of the industry, AGVs are the dream of many business managers, who see them as a promise to meet modern society's new challenges while remaining competitive.

AGVs, a response to new global challenges

The AGV market is quickly growing and constantly expanding into new sectors. In industrial, medical, agricultural, and many other environments, they allow, among others:

- To meet consumers’ growing needs and requirements in quality, time, and cost.

- To increase productivity by handling repetitive tasks more quickly and accurately.

- To ensure a 24/7 activity at a lower cost.

- To reduce operating costs.

- To improve people’s safety by exempting humans from certain repetitive tasks, which can cause musculoskeletal disorders and lead to demotivation and absenteeism.

- To redistribute human resources to value-added tasks that are more strategic for a company's development.

Electric motion solutions for all types of equipment and sectors

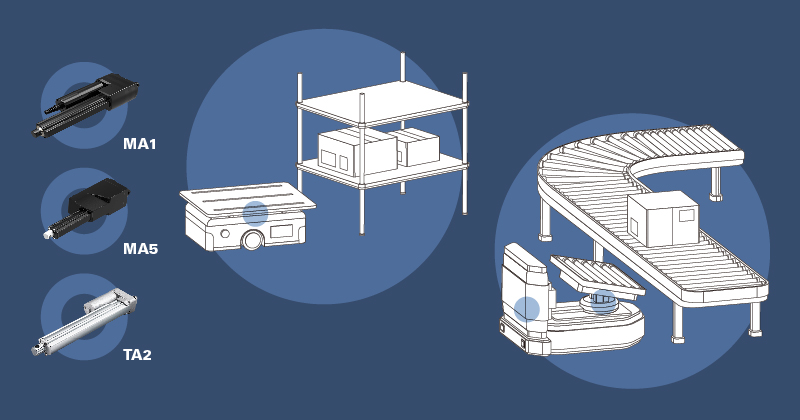

Electric linear actuators for logistics and industrial AGV

With an increasing demand for goods and ever-increasing delivery requirements, logistics is an essential competitive element for any business.

AGVs have transformed the supply chain, making it ever more efficient to meet customers’ needs. They can be found in warehouses preparing orders, loading and unloading containers, and moving goods. They are very versatile as they can also be found in specific locations such as airports, as one example, for baggage handling.

AGVs are also used on production sites. They free up the end of the production line, transport components or finished products from one station to another, and thus relieve the operators of unnecessary or repetitive movements.

TiMOTION designs compact and high-performance electric actuators, ideal for the operation of these robots.

Some AGVs need to fit under containers and require certain compactness, which impacts the available interior space for the electrical system, hence the importance of its small size.

The MA1 industrial electric linear actuator is ideal for adjusting the AGV’s charging platform height. It can push up to 4500 N and has an optional overload clutch to protect the equipment in case of overload.

It is also possible to imagine a horizontal movement to push a load on a work surface or a conveyor, for example. In this case, the TA2 electric actuator is perfectly adapted and can be integrated into restricted spaces. Moreover, it has optional signal limit switches that can bring more functionality to the equipment.

The MA5 electric actuator can tilt the charging platform by lifting only one side and thus slide the load from the AGV to another surface for fully automated handling.

To learn more about Logistics AGV, click here.

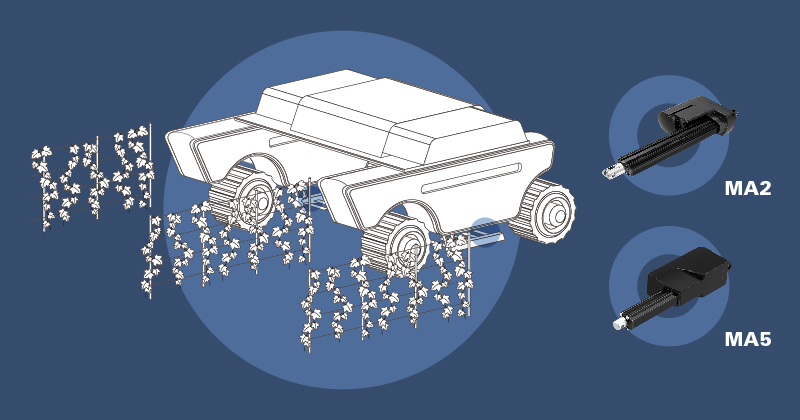

Electric linear actuators for agricultural AGV

Feeding an ever-growing population is a major challenge for agricultural actors who must produce more and more to remain competitive. Evolving expectations regarding the products’ nature (organic, pesticide-free) also require a new reflection on how food is cultivated.

Agricultural AGVs are an answer to these new challenges. Passing through the crop rows allows certain analysis, monitoring, and crop maintenance tasks to be carried out in an automated, precise, rapid, and uninterrupted way.

This technology allows agricultural actors to increase their productivity while making work easier, guarantee product quality with more regular and customized care, and answer the ecological challenge by offering organic and pesticide-free products.

By increasing crop and soil maintenance regularity, crops are always healthy and maintained. The soil retains an optimal quality and no longer requires any more polluting pesticides, harmful to the ecosystem.

Electric linear actuators allow the height adjustment and positioning of the AGV’s cultivation tools. They lower the tools at the row entrance and raise them at the row exit. They allow various hoeing, weeding, pruning, or other tool operations.

The MA2 industrial electric linear actuator is ideal for agricultural equipment. With a load capacity of up to 8,000 N in push and an optional IP69K, it is ideal for lifting and lowering farm tools at row entry and exit.

The MA5 electric actuator will adjust the tools’ spacing on each side of the crop and automatically adapt the agricultural equipment to the row width. Thus, each plant will be treated accurately and without the risk of damaging the crops. This industrial electric actuator is equipped with an optional greasing system for the joint between the inner and outer tube, which increases its degree of protection and lifespan.

Electric actuators are a good alternative to hydraulic systems since they present no risk of fluid leakage that could pollute the soil while meeting users’ new ecological expectations. Their optional IP rating, up to IP69K, makes them particularly suitable for harsh agricultural environments (water, dust, mud, bad weather).

The AGV can also be used in greenhouses to prepare carts or orders. The transport of vegetables from one point to another is automated, limiting unnecessary and risky movements for the farmers, and preserving product quality.

Here, the MA1 electric actuator will also be adapted for the AGV’s charging platform height adjustment.

Electric linear actuators for medical AGV

Increased patient volume, reduced nursing staff, hard work, and risk of contamination are all challenges that medical institutions face today.

The medical AGVs allow the handling of repetitive movements within medical institutions such as laundry, food, and waste transport and the delivery of pharmaceutical and medical equipment to the patient or operating rooms, usually performed by nursing staff.

Thus, the AGVs relieve the medical actors from unnecessary, tiring, or risky movements, which can cause musculoskeletal disorders.

In epidemic settings, the AGVs help limit viral contamination while maintaining optimal care for contagious patients by providing the necessary equipment for their well-being.

They also enable optimal and secure medical material needs replenishment and automated inventory management, freeing healthcare staff from cross-functional tasks and allowing them to provide superior patient care.

The TA37 electric linear actuator is specially designed for medical equipment. It can push up to 12,000 N and is very suitable for lifting and lowering the medical AGV’s charging platform.

It has an optional additional protection rating of up to IP66W*, making it particularly suitable for use in medical environments where cleaning and disinfection standards are high.

Moreover, its silent mechanism will preserve the comfort of those nearby and the tranquility of the medical space.

It is also possible to consider a horizontal actuation to move the load from the platform to a work surface. In this case, the TA29 medical electric actuator is ideal. Its compact design makes it easy to fit into a small space while offering a load capacity of up to 6,000 N in push.

*Washable = washable regarding TiMOTION standards.

Electric linear actuators for industrial cleaning AGV

In recent months, the pandemic has elevated the importance of hygiene and sanitary environment in public spaces. Intensive cleaning and regular disinfection have become an integral part of the global economy.

But with increasingly large spaces leading to longer and more regular cleaning, maintaining public spaces has become a significant challenge for their managers.

Beyond hygiene, maintenance is also an aesthetic issue as it guarantees a certain level of quality to users, ensures the environment’s sanitary conditions, and improves the company's image.

Industrial cleaning AGVs take care of these areas’ maintenance. With continuous cleaning, the environment is always optimal and meets strict sanitary standards.

Electric linear actuators allow cleaning tools such as rotary brushes to be lowered and raised as needed.

For lifting and lowering cleaning tools, the MA5 electric actuator is ideal. Compact and robust, it will fit easily into the mechanism of the cleaning AGV. Its optional IP69K rating makes it particularly suitable for cleaning machines, subject to water and dirt.

For smaller equipment with limited interior space, the TA38M electric actuator is also an interesting solution for brush adjustment. Its size-weight-performance ratio makes it a unique device on the market!

Electric linear actuators and gear motors for autonomous loading stations

The electric car market is quickly expanding and involves the parallel development of loading stations. Again, these tend to be automated, and charging AGVs are beginning to appear.

These autonomous loading stations move automatically to the vehicle for easy loading without user intervention. The charging AGVs allow support for a large number of vehicles to be charged simultaneously, in an automated way.

TiMOTION offers an electric motion solution for load arm adjustment. With its load capacity up to 3,500 N in push, the MA5 industrial electric actuator will adjust the height of the AGV’s load arm relative to the vehicle. A TGM2 gear motor will adjust the arm’s orientation, and the compact TA38M industrial electric actuator will complete the positioning of the load arm with precision in relation to the vehicle's socket.

Electric linear actuators offer many adjustment possibilities for your Automated Guided Vehicles. Robust and smooth, they support heavy loads and provide your equipment with reliable and secure movement. Beyond lifting and lowering their components, they also allow electrical adjustment of all kinds of doors, hoods, and accessories (camera, lamp, sensors, etc.), whatever the robot or its environment.

The TA38M electric actuator is also suitable for this type of operation. Its stroke up to 200 mm makes it ideal for the actuation of hatches and hoods. The VN1 electric actuator can also be used to open and close all kinds of hatches. Its specific attachment gives it a smaller footprint, suitable for compact AGVs.

The TA20 electric actuator will allow for accessories adjustment. Its three-piece telescopic design allows for a long stroke while maintaining a minimal retracted length, ideal for installation in tight spaces.

TiMOTION electric linear actuators can be equipped with various optional sensors (Hall effect sensors, reed sensors, potentiometers) that allow feedback on the position of the actuator stroke and easier management of the motion systems.

Moreover, electric actuators are an efficient alternative to hydraulic and pneumatic systems. They are oil-free, maintenance-free, and require no post-installation intervention.

The right electric motion solution for every environment, our electric devices offer many options and are compatible with most control systems. We customize our systems to your needs and work with you to develop a tailor-made project.

To learn more about our products, please contact your nearest sales office.