2018/03/06

Motion Solutions Revolutionizing The Agriculture Industry

News and Articles

The Importance of Agriculture

The development of agriculture can be dated back to over 10,000 years ago and has since played a key role in the evolution of human civilization. The Neolithic Revolution caused hunter-gatherer lifestyles to be replaced in favor of permanent settlements and reliable food supply, which prompted the growth of cities and civilizations. The next major shift was notably the Agricultural Revolution that occurred in the 1800s. During this period, machinery and equipment were introduced to the farming industry, making work less difficult and time-consuming. Today, machinery has become the backbone of the agriculture industry. Due to this, it is imperative that farmers have access to equipment that is powerful, durable, and reliable.

Operational Challenges of the Industry Today

The farming process requires equipment to be accurate and resilient; component parts must undergo stringent quality control for the system to work properly. There are multiple challenges that can lead to malfunction and put both equipment and operators at risk. These include harsh outdoor weather conditions, high temperatures, rusting, corrosion, and loss of lubrication. All of these factors affect the production value of the machines.

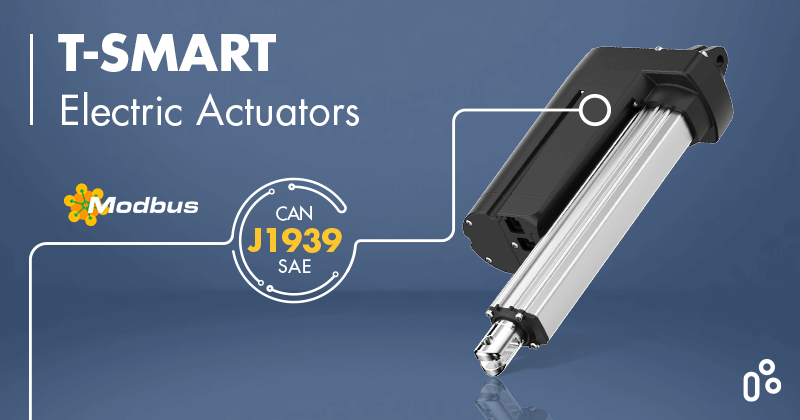

The electric linear actuator offers a complete automation solution and can withstand a variety of outdoor elements. Electric actuators can be integrated into sophisticated control systems, which give operators precise position feedback and flexible control over acceleration and velocity.

Compared to pneumatic and hydraulic systems, the electric linear actuator is easier to install, takes up less space, and has no hoses or pumps that require routine maintenance. Additionally, electric actuator systems are clean, non-toxic, and energy-efficient. They fulfill the ever-increasing demands and legislation concerning environmentally sound equipment.

The following are some applications in which electric linear actuators can play a role in improving the agriculture industry:

-

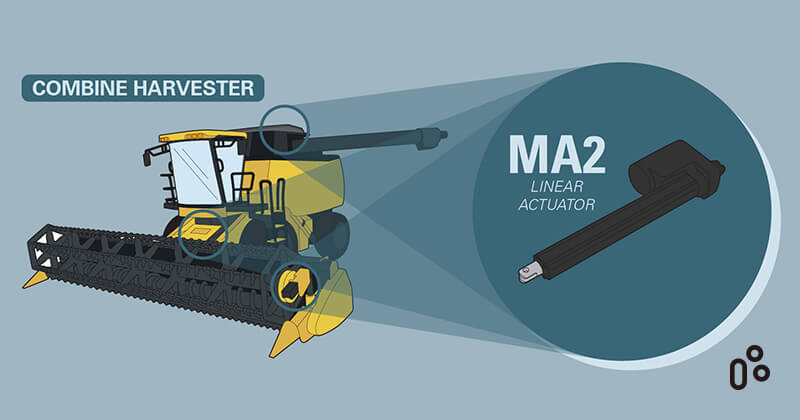

Combine Harvesters

The combine harvester is designed to withstand weather conditions and undergo mechanical stress that harvesting places on the machinery. Electric actuators assist with smooth, accurate functioning to ensure user-friendly adjustment settings amongst different varieties of crops. Electric actuator solutions include:

- Adjustment of the concave dependent on the crop

- Electric open and close of the grain tank covers for inspection

- Engagement and disengagement of the thresher and cutter units

- Speed regulation of the header

-

Seed drill

The seed drill requires a high level of accuracy and precision. The right amount of seed has to be spread in a precise manner in order to yield a cost-effective crop. These are some of the ways that electric actuator systems can be utilized in a seed drill:

- Adjustment of the dosing unit for crop/seed rotation

- Raising and lowering markers to reduce process waste

- Opening and closing of the tank cover on the seed drill

-

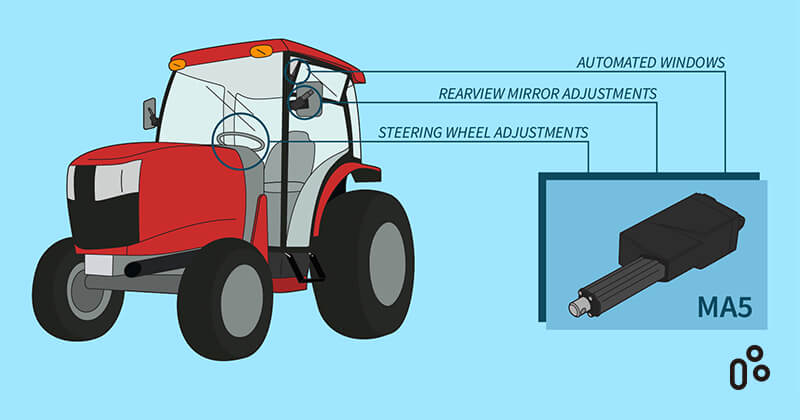

Tractors

The tractor is used for a variety of operations and must be able to maintain a high level of control even under unfavorable weather conditions. Due to their compact size and programmable control systems, electric actuator systems provide security for users and simple installation for manufacturers. On a tractor they can function in the following ways:

- Adjustment of the PTO speed

- Electric adjustment of gear shift, PTO, and opening/closing of the windows

- Hood lift applications for easy access and routine maintenance

-

Sprayers

Precise adjustment is a key factor in effective spraying equipment. During windy weather, it is especially important to control the direction of the spray to minimize waste and maximize efficiency. Electric actuators can have a big impact by providing accurate spraying and easy control. The following are a few notable sprayer components that can be improved through electric actuation:

- Outlet nozzle height and angle control

- Activating or deactivating the spray arm

- Fine adjustment of spray arm to be able to spray exactly where needed

-

Fertilizer spreaders

In order to function effectively, spreaders require a high level of precision. The electric actuator offers an innovative positioning system that ensures that the accurate amount of fertilizer and pesticide is spread to each specific field. These are the following ways that electric actuators can increase the efficiency of spreaders:

- Adjustment of the spreader pattern depending on the type of fertilizer

- Ensure accurate dosing of fertilizer even when speed varies

- Automation of the start/stop feature to the supply of fertilizer in the headland

- Eased control of the open and close of the tank cover

-

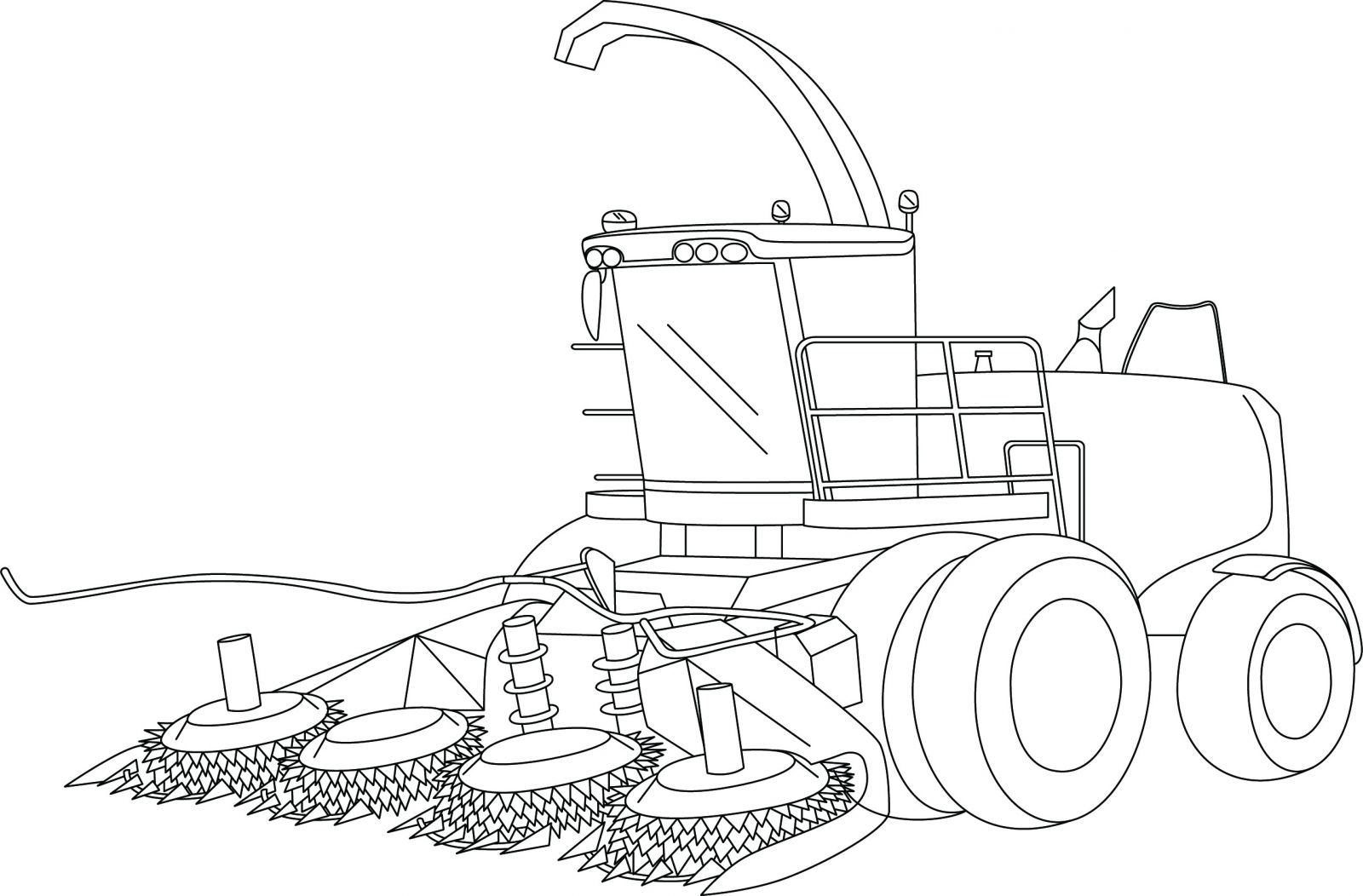

Forage Harvesters

Harsh conditions, along with a wide variety of crops, demand that forage harvest machinery is durable and flexible. Electric linear actuators facilitate optimal performance through integrated controls and minimal maintenance. Notable electric actuator functions on a forage harvester include:

- Adjustment of crop accelerators and corn crackers

- Position feedback from control systems

Electric Linear Actuator Solutions for Agricultural Equipment

-

MA2 Series

TiMOTION’s MA2 series linear actuator was specifically designed for applications that face harsh working environments and require ruggedness and durability. Its optional IP69K protection ensures it will withstand high temperature, high-pressure water jets, and the ingress of dust and other solid contaminants. The MA2 also has optional Reed switches along the outer tube which allow users to adjust the stroke length. For improved control and accuracy of motion, the MA2 can be customized with many different feedback options depending on your application requirements.

-

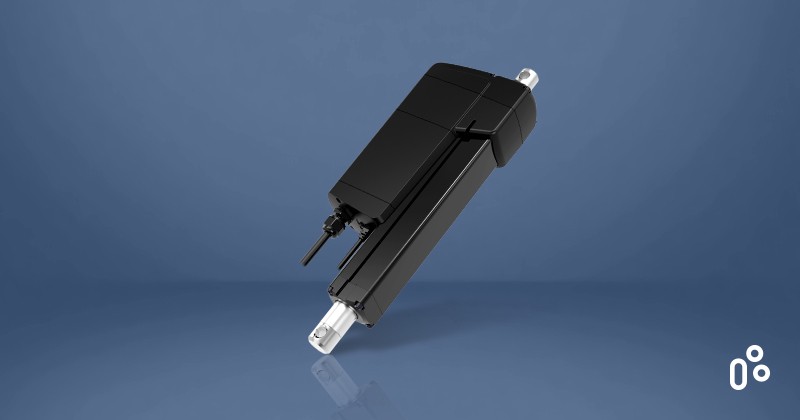

TA2/TA2P Series

TiMOTION’s TA2 and TA2P series linear actuators are compact, robust, and capable of performing well in certain outdoor environments. This linear actuator is perfect for use in small spaces where force or capability cannot be sacrificed. Options include feedback sensors, signal-sending limit switches, and 90-degree clevis mounting. Industry certifications for the TA2 and TA2P linear actuators include EMC and RoHS. The TA2P is also UL73 certified.

-

JP Series

TiMOTION’s JP4 series inline linear actuator is most similar to the JP3 but was designed for industrial applications that require higher load and speed. Its IP69K protection ensures it will withstand high temperature, high-pressure water jets, and the ingress of dust and other solid contaminants. For synchronization and position feedback, the JP4 and JP3 can be equipped with Hall sensors.

Conclusion

As society continues to evolve, so must the equipment that yields sustenance for the population. Electric actuators provide precise adjustments and integrated control systems that maximize efficiency and reduce waste in agricultural machinery. The simple yet powerful system easily replaces hydraulic components to ensure that equipment maximizes productivity and reduces long-run costs. For more information on TiMOTION’s Industrial-grade actuator solutions, visit our website or contact a member of our sales team.