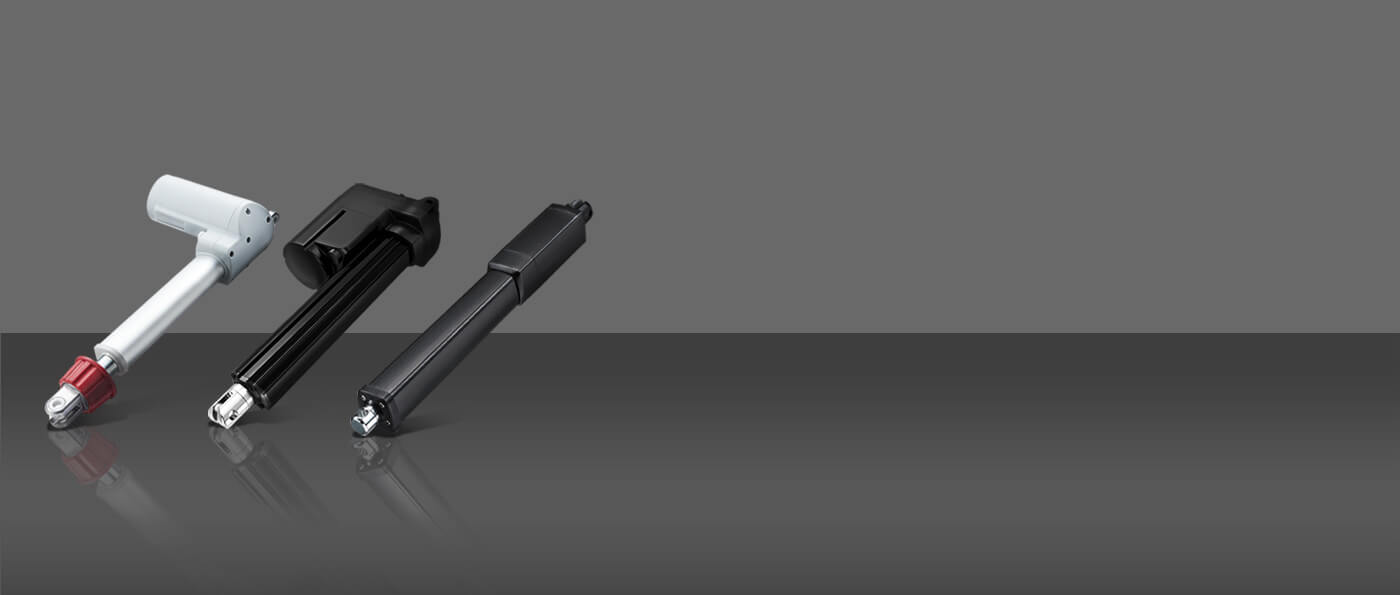

TiMOTION is an industry-leading provider of custom actuator / electric linear actuators and supporting products.

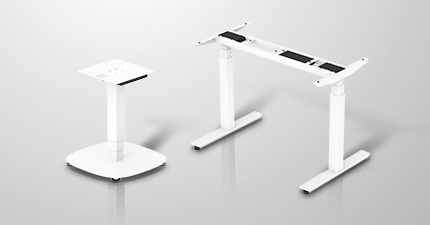

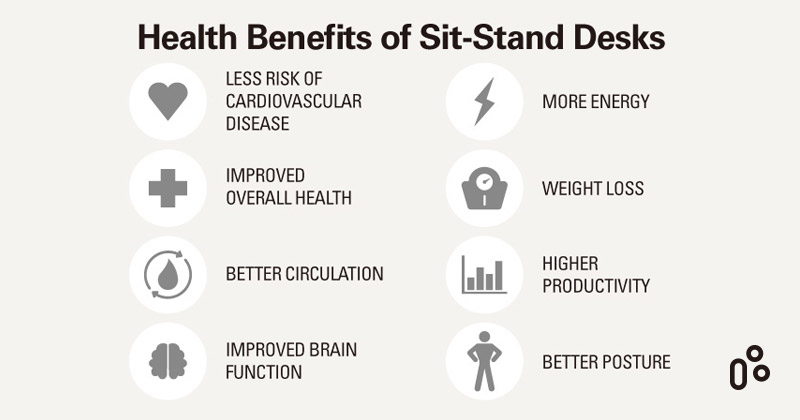

Our team specializes in innovative and customized solutions for manufacturers of industrial, furniture, and medical equipment. We pride ourselves in providing the best possible solutions to each and every one of our customers.

At TiMOTION, we know that any problem can be solved with the right technology. Custom actuator products and electric linear actuators are used to enhance applications that hydraulic and pneumatic systems just don't fit. As your business partner, TiMOTION aims to provide the highest quality, customizable components at competitive prices.

We believe in what we do and the products we create.

We are TiMOTION.

Our Markets

FAQ

Our products are UL recognized. We ensure our products go through the proper outside testing to receive certification.

We have standard options for each of our products; however, every actuator is customized to our customers based on their specific product needs.

Please go to our “contact page” and select your location to find your nearest sales representative. You can also fill our contact form with your details, and we will contact you shortly.

TiMOTION works exclusively with Original Equipment Manufacturers (OEMs). Therefore, we do not stock, distribute, or sell any single product. For any questions, replacement, or purchase of an individual component, please contact your specific equipment manufacturer. Components are often covered by their warranty and may be available in stock for single unit distribution.